Composite material (bimetal)

Trading and industrial company SC Metal Market LLC is a well-known supplier of bimetal stainless steel plates, clad plates and strips.

The main consumers of the composite material are the leading machine-building industries: petrochemical industry (reactor vessels, fractionators, vessels and etc.), atomic and power industry (pipe sheets, vessels and etc.), shipbuilding (hulls, transitional elements, vessels, containers and etc.)

According to estimations total consumption of thick stainless bimetal plates in Russia is approximately 20-30 thousand m? per year. Around 70-80% of the total amount are imported from Germany, France, and the USA at prices 1,5-2 times higher than ones for domestic plates at the similar quality of plates.

- component parts out of bimetal plates (or any other material);

- forged dished ends of diameter 219mm up to 3200mm;

- cover plates with diameter up to 9400mm;

- submersible equipment for zinc plating bath;

- special explosion chamber upon request.

The most promising manufacturing method is explosive cladding. It allows to obtain bimetal plates and other products of almost unlimited dimensions and of various metals and alloys.

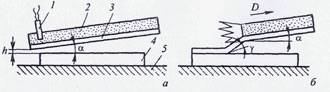

Explosive cladding is a process of bonding of 2 metal plates, which occurs at their high speed impact. Impact of metals takes place when clad metal is thrown on the plate of the base material by the explosion of the charge of the blasting explosive. One of the important aspects here is a process of preliminary works, which accuracy is a key for execution of the explosive cladding itself and getting bimetal plates of high quality.

Drawing 1. Scheme of explosive cladding before (а) and while explosion (б)

Impact of clad and base plates is accompanied by plastic deformation which results in local heating of surface layers of metals. In the issue of deformation and heat physical contact and activation of welding surfaces occur, and bonding takes place.

- mechanical characteristics of metals are fully remained ;

- higher bonding quality between metals;

- weak areas, which usually occur during the process of high temperature exposure, are missing (during explosion due to rapidity of the process heat transmission doesn’t occur);

- short manufacturing time;

- less costly in comparison with other manufacturing methods;

- manufacturing of any quantity starting from 1 plate up to several hundreds of tons per month.

On the new base, which was formed in Nizhegorodskaya Region, the following products were manufactured:

- January-February, 2008 , 55 tons ( 16 plates, 144 m2) of bimetal plates of steel grades 09Г2С+08Х13 in the shape of plates with dimensions 6000х1500х57mm for further manufacturing of separators by Gazprom neftekhim Salavat JSC.;

- February, 2008, 3 tons ( 3 plates, 27 m2) of bimetal plates of steel grades 09Г2С+08Х13 with dimensions 29х1500х3000mm;

- May, 2008, one bimetal plate of steel grades 09Г2С +МС1(cuprum) with dimensions 1500х500х90mm (thickness of Cuprum 20mm), for the crystallizer’s wall of the steel continuous casting plant;

- April-May, 2008, 60 tons (55 plates, 495 m2) of bimetal plates of steel grades 09Г2С + Х6СRNITI 1810 (Russian analogue 08Х18Н10Т) with dimensions 16х1500х6000mm for OJSC «VNIIneftemash»;

- May, 2008, 3,5 tons (2 plates, 18 m2) of bimetal plates of steel grades 12ХМ +AISI 321 with dimensions 24х1500х6000mm;

- April-May, 2009, 45 tons (34 plates ,306 m2) of bimetal plates of steel grades 09Г2С+ 08Х17Н13М2Т with thickness 8mm, 12mm , 16mm and 20mm, width 1500mm, length 6000mm;

- June, 2009, 3,5 tons ( 1 plate ) of bimetal plates of steel grades 09Г2С+ 12Х18Н10Т with dimensions 150х1520х 2045mm, thickness of stainless steel – 30mm, for sheet rolling for Severstal;

- June, 2009, 19 tons (9 plates ,81 m2) of bimetal plates of steel grades Ст3.сп5 + 10Х17Н13М2Т, with dimensions 29х1500х6000mm;

All bimetal plates are in accordance with the requirements of GOST 10885-85 for continuity class 0 and 1 at 100% ultrasonic testing.

Manufacturing process of bimetal and finished goods are fully certified. Manufacturing of bimetal plates complies with the standards approved by JSC NPO «CNIITmash» and OJSC «VNIIneftemash»

Range of the materials that may be bonded by explosive welding is very wide, up to several hundreds of combinations of various steels and alloys. In the order thickness of cladding stainless steel layer and continuity class of the bond are to be specified.

Steel is divided by:

thickness of stainless steel layer — normal and higher than normal — К;

continuity class of the bond — classes 01, 0, 1, 2, 3.

Two-layer plates are produced of the thickness from 4 up to 60mm. Upon request of the client plates may be produced of the thickness from 60 up to 120mm. The thickness of the base material and clad material is specified in the Table 1.

in mm

| Clad material grades | Base material steel grades | ||||||||||

| ВСт3сп/

A 283 GrC/ A 285 GrC/ |

10/

C10E |

20К

A 515 Gr 60/70 |

09Г2/

7Mn6 |

16ГС/

A 517 Gr 60 |

09Г2С/

A 517 Gr 65/70 |

10ХСНД/

A 736 Gr A, B |

10ХГСН1Д/

---- |

12МХ/

A 204 Gr A, B/ A 387 Gr2 |

12ХМ/

A 204 Gr A, B / A 387 Gr12 |

10×2М1/

A 387 Gr22 CL 2 |

|

| 08X13 /

AISI 403/ 429 |

+ | - | + | + | + | + | - | - | + | + | - |

| 08X17Т/

AISI 430 Ti/ 439 |

+ | - | + | - | - | - | - | - | - | - | - |

| 15X25Т/

AISI 446 |

+ | - | + | - | - | - | - | - | - | - | - |

| 08X18Н10Т/

AISI 304/321 |

+ | - | + | - | + | + | + | - | + | + | + |

| 12X18Н10Т/

AISI 321 |

+ | - | + | + | + | + | + | + | + | + | - |

| 10X17Н13М2Т/

AISI 316 |

+ | - | + | - | + | + | - | - | - | - | - |

| 10X17Н13М3Т/

AISI 316 Ti |

+ | - | + | - | + | + | - | - | - | - | - |

| 08X17Н15М3Т/

AISI 316 N |

+ | - | + | - | + | - | - | - | - | - | - |

| 08X22Н6Т/

--- |

+ | - | + | - | - | - | - | - | - | - | - |

| 06ХН28МДТ/

N08028 |

+ | - | + | - | + | - | - | - | - | - | - |

| ХН65МВ, ХН65МВУ/

Hastelloy C-276 |

- | - | - | - | + | - | - | - | - | - | - |

| Н70МФВ-ВИ/

Nickel Alloy |

- | - | - | - | + | - | - | - | - | - | - |

| Monel НМЖМц 28–2,5–1,5/

B127 (N04400) |

+ | - | + | - | - | - | - | - | - | - | - |

| Nickel НП-2/

Nickel NP-2 |

+ | + | - | - | - | - | - | - | - | - | - |

Attention! Analogues are specified both, precise and close .

Remark. Production of two-layer plates with the combination of layers «-» is to be agreed between the client and manufacturer.

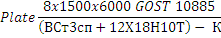

Example of identification of two-layer plates with thickness - 8mm, width – 1500mm, length – 6000mm, base material ВСт3сп, category 2 acc. GOST 380–71 and stainless steel layer 12X18Н10Т according to GOST 5632–72, without continuity test of the bond, with thickness of stainless steel layer higher than normal:

Delivery time depends on the order quantity and order range :

- manufacturing of plates up to 500 m2 – no more than 2 months;

- manufacturing of plates of materials from stock – 1 month.

In your enquiries for bimetal plates we ask you to state steel grades, dimensions of plates, quantity, dimensions of bimetal plates needed, required delivery time, standard for bimetal plates. We guarantee that the price will be calculated within a short period of time. Please note that accuracy of quotes and quoting time will depend on the availability of the detailed parameters of your enquiry. It is very simple to purchase bimetal plates from SC Metal Market: send your enquiry to info@supplysteel.ru .

Труба бесшовная

Труба электросварная

Трубы DIN, ASTM

Труба нефтегазопроводная

Труба нержавеющая

Газлифтные трубы

Арматура термоупрочненная

Арматурная сталь

Уголок

Швеллер

Армированная сталь

Заготовка

Сталь с морским регистром

Нержавеющий металлопрокат

Алюминиевый профиль

Шестигранник

Круг стальнoй (пруток)

Сетки металлические

Биметалл

Composite material (bimetal)

Лист просечно-вытяжной

Метизы DIN, EN, BS, ASME, ANSI

Биметаллы для электротехники

20Х23Н18

20Х20Н14С2

10Г2С1

5ХНМ

30ХГТ

32НКД

Полезная информация